In the intricate web of pipelines that crisscross beneath our feet, ensuring their integrity is paramount. Pipeline damage can lead to severe consequences, both economically and environmentally. In this article, we delve into the world of pipeline repair clamps, exploring their role, types, installation process, and the benefits they offer.

Introduction

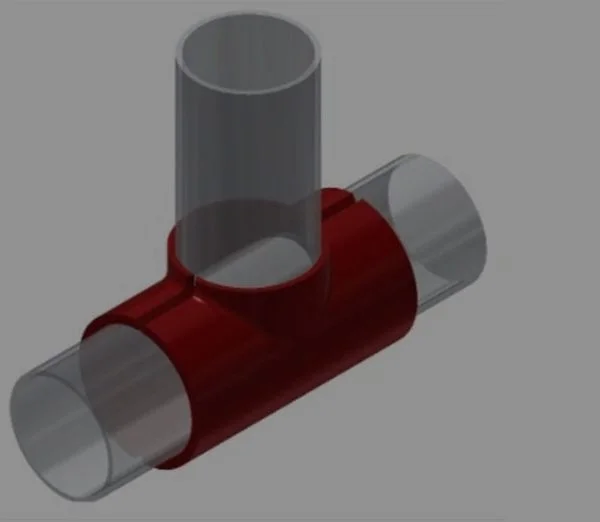

Definition of Pipeline Repair Clamps

Pipeline repair clamps are specialized devices designed to address leaks, cracks, or damages in pipelines swiftly. Acting as a robust solution, these clamps play a crucial role in maintaining the functionality and safety of pipelines across various industries.

Importance of Timely Repairs

Timely repairs are essential to prevent minor issues from escalating into major catastrophes. Pipeline repair clamps provide a quick and efficient way to address damages, minimizing the risk of spills, leaks, and subsequent environmental damage.

Common Causes of Pipeline Damage

Pipelines face numerous threats, and understanding the common causes of damage is vital for effective maintenance.

Corrosion

Corrosion, a persistent challenge, can weaken pipelines over time. Pipeline repair clamps offer a reliable solution to counteract the effects of corrosion.

External Forces

External forces, such as natural disasters or construction activities, can cause sudden damage. Repair clamps act as a first line of defense against such unforeseen events.

Material Failure

In some cases, the materials used in pipeline construction may fail over time. Repair clamps provide an efficient means of addressing these material-related issues.

The Role of Pipeline Repair Clamps

Quick and Efficient Repairs

One of the primary advantages of pipeline repair clamps is their ability to facilitate rapid repairs. This quick response is crucial in preventing extended downtimes and reducing the potential for environmental harm.

Versatility in Application

Pipeline repair clamps are versatile and can be applied to various pipeline materials, including steel, iron, and PVC. This adaptability makes them a go-to solution for a wide range of industries.

Types of Pipeline Repair Clamps

Understanding the different types of repair clamps is essential for choosing the most suitable one for a specific application.

Full Encirclement Clamps

Full encirclement clamps completely surround the damaged section of the pipeline, providing robust support and sealing.

Wraparound Clamps

Wraparound clamps are designed to wrap around the pipe, offering a secure and adjustable solution for different pipeline diameters.

Bell Joint Clamps

Bell joint clamps are specialized for joint leaks, providing a targeted solution for specific areas of the pipeline.

Choosing the Right Pipeline Repair Clamp

Material Considerations

Selecting the right material for the repair clamp is crucial to ensure compatibility with the pipeline material and the nature of the damage.

Size and Diameter

Matching the size and diameter of the repair clamp to the pipeline is essential for a secure and effective repair.

Operating Conditions

Consideration of the operating conditions, such as pressure and temperature, is necessary to choose a repair clamp that can withstand the specific environment.

Installation Process

Inspection and Preparation

Before installation, a thorough inspection of the damaged area is conducted. Preparation involves cleaning and ensuring the surface is ready for the clamp.

Step-by-Step Installation Guide

The installation process involves securing the clamp in place, ensuring a tight seal, and verifying the integrity of the repair.

Advantages of Using Pipeline Repair Clamps

Cost-Effective Solution

Compared to extensive pipeline replacement, repair clamps offer a cost-effective alternative, saving both time and resources.

Minimizing Downtime

The quick installation of repair clamps helps minimize downtime, allowing for prompt resumption of regular operations.

Long-Term Reliability

Pipeline repair clamps provide a reliable long-term solution, offering durability and stability in diverse operating conditions.

Case Studies

Successful Applications

Real-world examples showcase the effectiveness of pipeline repair clamps in addressing various issues and ensuring the continued operation of critical infrastructure.

Testimonials from Users

Feedback from industries that have implemented repair clamps highlights their satisfaction with the performance and reliability of these solutions.

Maintenance Tips

Regular Inspections

Regular inspections of pipelines, coupled with proactive maintenance, can identify potential issues before they escalate, extending the lifespan of the infrastructure.

Repair vs. Replacement Considerations

Understanding when to repair and when to replace a section of the pipeline is crucial for optimizing maintenance efforts.

Future Trends in Pipeline Repair Technology

Innovations in Clamp Designs

Ongoing advancements in clamp designs aim to enhance efficiency, durability, and ease of installation.

Technological Advancements

Integration of technology, such as sensors for real-time monitoring, is a promising trend in the evolution of pipeline repair solutions.

Environmental Impact

Sustainable Practices in Pipeline Repairs

Exploring sustainable materials and practices in pipeline repairs contributes to minimizing the environmental footprint of maintenance activities.

Eco-Friendly Materials

The use of eco-friendly materials in manufacturing repair clamps aligns with the growing focus on environmentally conscious practices.

Regulatory Compliance

Meeting Industry Standards

Adhering to industry standards is paramount for ensuring the effectiveness and safety of pipeline repair solutions.

Legal Requirements for Pipeline Repairs

Navigating legal requirements and regulations is essential to avoid penalties and ensure compliance with established norms.

Challenges and Solutions

Addressing Common Issues

Identifying and addressing common challenges in pipeline repairs ensures the continued reliability of repair clamp solutions.

Overcoming Technical Hurdles

Ongoing research and development efforts aim to overcome technical hurdles, ensuring that repair clamps evolve to meet the changing needs of the industry.

FAQs

-

What are pipeline repair clamps?

-

Pipeline repair clamps are specialized devices designed to address leaks, cracks, or damages in pipelines swiftly.

-

-

How do I choose the right clamp for my pipeline?

-

Consider factors such as material compatibility, size, diameter, and operating conditions when selecting a pipeline repair clamp.

-

-

Can pipeline clamps be used for different materials?

-

Yes, pipeline repair clamps are versatile and can be applied to various pipeline materials, including steel, iron, and PVC.

-

-

Are pipeline repair clamps a permanent solution?

-

Pipeline repair clamps provide a reliable long-term solution, offering durability and stability in diverse operating conditions.

-

-

What should be considered during clamp installation?

-

The installation process involves thorough inspection, preparation, securing the clamp in place, and verifying the integrity of the repair.

-

Conclusion

In the dynamic landscape of pipeline maintenance, repair clamps emerge as a versatile and efficient solution. Their role in quick and reliable repairs, coupled with advancements in technology and sustainable practices, positions them as a crucial component in safeguarding critical infrastructure. As industries continue to evolve, the use of pipeline repair clamps will likely remain integral to ensuring the uninterrupted flow of resources.