310S has emerged as a standout performer in stainless steel alloys, celebrated for its exceptional versatility in various applications. While it’s renowned for its superb performance under high-temperature conditions, the versatility of 310S stainless steel pipes extends far beyond mere thermal challenges. This comprehensive exploration delves into the diverse applications where 310S stainless steel pipe shine, showcasing their adaptability, corrosion resistance, and structural integrity across various industries.

.

Understanding the Alloy: The Foundation of Versatility

310S stainless steel is a modified version of its predecessor, 310, with the addition of low carbon content. This alteration enhances its weldability and corrosion resistance, making it an alloy of choice for applications where exposure to elevated temperatures and corrosive environments is commonplace. The alloy’s primary composition includes chromium and nickel, imparting exceptional resistance to oxidation and corrosion.

High-Temperature Applications: A Strong Starting Point

The initial acclaim for 310S stainless steel pipes stems from their remarkable performance in high-temperature environments. These pipes find prolific use in industries such as heat treatment, furnace components, and thermal processing units. With an ability to withstand temperatures well beyond 1000°C (1832°F), 310S stainless steel pipes serve as stalwart guardians in applications where structural integrity under extreme heat is non-negotiable.

Chemical and Corrosive Resistance: A Corrosion-Proof Shield

Beyond high temperatures, 310S stainless steel pipe demonstrate outstanding resistance to corrosion and chemicals. This property makes them invaluable in industries dealing with corrosive substances, acids, and challenging atmospheric conditions. Chemical processing plants, petrochemical industries, and offshore platforms benefit from the corrosion-resistant shield that 310S stainless steel provides, ensuring longevity and reliability in harsh environments.

Petrochemical Prowess: Withstanding the Rigors of the Oil and Gas Sector

In the expansive world of oil and gas, where conditions are demanding and unpredictable, 310S stainless steel pipes find a natural fit. Their corrosion resistance and high-temperature stability make them ideal for various applications, including pipelines, refineries, and offshore drilling rigs. The alloy’s ability to combat the corrosive effects of oil, gas, and chemical compounds contributes to the robustness of the petrochemical infrastructure.

Seamless Construction: The Art of Uninterrupted Strength

The seamless construction of 310S stainless steel pipes adds a layer of reliability to their versatility. Seamless pipes eliminate the risk of weak points and potential leakage, ensuring a continuous, uninterrupted flow in critical applications. This makes them particularly suitable for industries where fluid or gas containment without compromise is paramount.

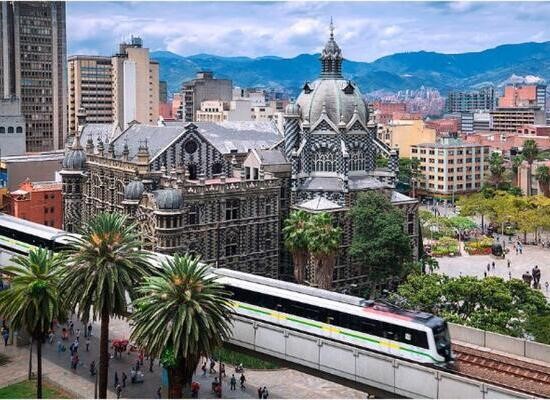

Architectural Brilliance: Aesthetic Appeal Meets Structural Integrity

Beyond industrial applications, 310S stainless steel pipes make a mark in the architectural realm. Their aesthetic appeal and structural integrity position them as a choice material for architectural accents, structural components, and even artistic installations. The alloy’s resistance to corrosion ensures that it maintains its visual allure over time, making it a preferred option for architects and designers seeking both form and function.

Welding Wonders: Techniques for Joining 310S Stainless Steel Pipes

Weldability is a crucial factor in the versatility of any stainless steel alloy. 310S stainless steel pipes, with their low carbon content, exhibit excellent weldability. This opens up a realm of possibilities in terms of fabrication and construction. Welding techniques, including TIG and plasma welding, are commonly employed to seamlessly join 310S stainless steel pipes, ensuring structural integrity without compromising the alloy’s corrosion resistance.

Food and Beverage Industry: Hygiene and Corrosion Compliance

In industries where hygiene is non-negotiable, such as food and beverage processing, 310S stainless steel pipe find a fitting role. Their resistance to corrosion and chemicals aligns perfectly with the stringent hygiene standards of the industry. From processing equipment to conveyance systems, 310S stainless steel pipes contribute to producing safe and high-quality consumables.

Power Generation: Enduring the Rigors of Energy Production

The power generation sector, encompassing thermal power plants and energy production facilities, relies on materials that can endure the rigors of continuous operation and fluctuating temperatures. 310S stainless steel pipes, with their ability to withstand high temperatures and resist corrosion, play a crucial role in various components, including boiler tubes and heat exchangers, contributing to the efficiency and reliability of power generation processes.

**Conclusion: The All-Encompassing Legacy of 310S Stainless Steel Pipes**

In conclusion, the versatility of 310S stainless steel pipes transcends the boundaries of conventional high-temperature applications. From architectural marvels to critical components in power generation, petrochemical industries, and beyond, these pipes embody a legacy of adaptability, strength, and resilience. Their corrosion resistance, weldability, and aesthetic appeal make them a formidable choice across industries, underscoring their role as a material that doesn’t just withstand challenges but thrives in diverse and demanding environments. As technology evolves and industries push the boundaries of what’s possible, the legacy of 310S stainless steel pipes as a versatile and reliable material continues to unfold, leaving an indelible mark across the spectrum of human ingenuity and industrial progress.